vickers hardness test discussion|vickers hardness test procedure pdf : commercial Perform analysis from Vickers hardness testing data. Hardness is a characteristic of a material not a physical property. Hardness is defined as resistance to indentation and determined by measuring the depth of the . WEBAdmin Pandabet.io. Senha. Login. Vuexy admin is super flexible, powerful, clean & modern responsive bootstrap 4 admin template with unlimited possibilities.

{plog:ftitle_list}

10 de nov. de 2022 · Updated 2 days ago. OUÇA AGORA O NOVO CD DO FLAGUIM MORAL - REPERTORIO ATUALIZADO NOVEMBRO 2022 ( 10 MUSICAS NOVAS ) LINK: .

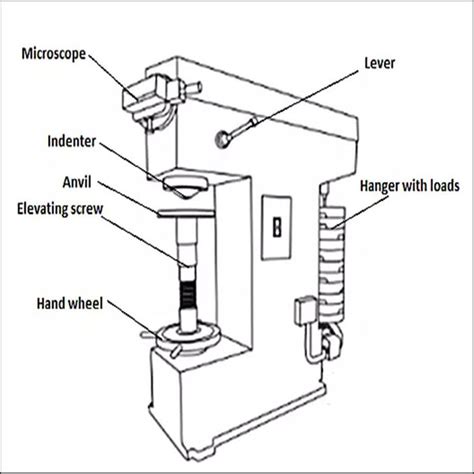

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess a material's hardness.Perform analysis from Vickers hardness testing data. Hardness is a characteristic .Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .Perform analysis from Vickers hardness testing data. Hardness is a characteristic of a material not a physical property. Hardness is defined as resistance to indentation and determined by measuring the depth of the .

The advantages of the Vickers hardness test is the extremely accurate readings can be taken and just one type of indenter is used for all types of metals. The Vickers test is capable of testing soft and hard material. The .Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of the .Learn all you need to know about Vickers microhardness testing and microhardness testing machines – with knowledge, insight and troubleshooting tips from Struers, one of the world’s leading Vickers micro hardness tester .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] .The Vickers test can be used for all metals and is one of the widely used test among hardness tests. The unit of hardness is known as the VICKERS PYRAMID NUMBER (HV) or DIAMOND PYRAMID HARDNESS (DPH). The hardness .The Vickers hardness test is used across various industries for different applications. Metallurgy: To determine the hardness of metals & their alloys. . Post-analysis discussion and input from Infinita subject matters was execptional and extremely helpful in guiding our investigations.” .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – .Discussion (CO4:PO9) 5; Conclusions (CO4:PO9) 5; Overall impression of report (CO4:PO9) 5. . The Vickers hardness test method also referred to as micro hardness test method is mostly used for small parts, thin sections or .

Vickers Hardness (Mean±SD) Empty Cell: Before grinding After grinding; Curtis et al., 2006: Lava frame: Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load (9.807 N) over 15 s to induce a diamond-shaped indent. The size of .E74 Practice of Calibration of Force-Measuring Instruments 3.1.5 Vickers hardness test, n—an indentation test in which for Verifying the Force Indication of Testing Machines a Vickers square-based pyramidal diamond indenter having E140 Hardness Conversion Tables for Metals Relationship specified face angles is forced under specified . (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.The Rockwell hardness test and Vickers hardness test are two commonly and widely used techniques among the many hardness testing methods. They can test different types of materials. Rockwell and Vickers hardness tests adopt other principles and testing methods, respectively. They have their own unique advantages and applicable scenarios.

What is this discussion about in one brief sentence? Select a category and describe a story. Create Topic . Community Discussions . The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a specific load. A load ranging from 1 gf to 100 kgf is applied to .The Vickers Hardness Testing is a cornerstone technique for evaluating the hardness of assorted materials, mainly metals and their types. Formulated in 1921 as a simpler recourse to the Brinell test, it estimates a material’s resistance to deformation under a consistent burden. . Post-analysis discussion and input from Infinita subject .Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of the . Steel and Aluminum to vicker hardness value. DISCUSSION: 1. What are possible sources of error? 2. Were your errors within reasonable limits (< 10%)?

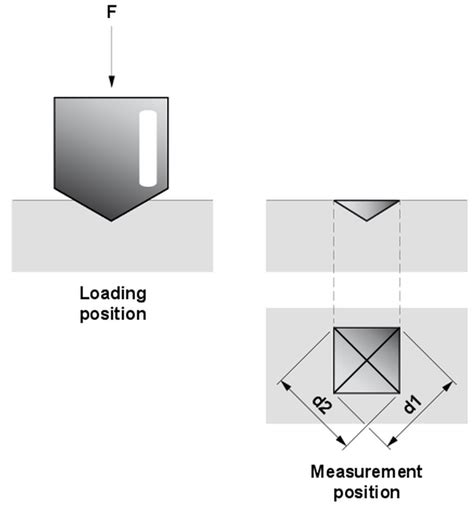

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384). 5. PAGE 4 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a test force of between 1gf and 100kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the .Figure 3.17 Vickers’s hardness for the cold rolled high Mn-TWIP steels 3.2.1. Thermal fatigue samples . Vickers hardness test were done for the thermal fatigue samples in both macro and micrometric length scale. Figures 3.18 and 3.19 is showing the Vickers hardness values for cold and hot rolled respectively at macro-metric length scale.

The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .The Vickers hardness test method, otherwise called a microhardness test method, is used for small objects, thin sections, as well as the case depth work. Due to the small indentation in a Vickers test, it can test very thin materials . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's hardness. The Vickers test employs a .

testo 320 basic flue gas analyzer

3.1.5 Vickers hardness test, n . Vickers or Knoop hardness test blocks. 3.2.8.1 Discussion—A hardness standardizing machine dif-fers from a hardness testing machine by having tighter toler-ances on certain parameters. 3.3 Equations: 3.3.1 The average d .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Rockwell, Brinell, and Vickers hardness testing methods are generally used for different scenarios and situations. However, hardness testing professionals have sometimes found it hard to agree on the most suitable method based on their differences. The differences will help you indicate the most appropriate method for your peculiar hardness .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.Vickers hardness test is a micro testing method used for some specified cases. Sometimes it becomes necessary to change the hardness value from one scale to another. Here we compare the Vickers hardness method with the Rockwell method and their conversion charts. + 86 755 61301520; [email protected]; Search. Home;

Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically in order to determine the hardness . Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s experience. In .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

Vickers hardness testing uses a pyramidal indenter and a load-on, load-off procedure, which gives geometrically similar impressions regardless of the penetration depth. Two characteristic lengths are measured on the Vickers indent, the indent diagonals, and an average diagonal length is used to calculate the impression area. . Discussion. As .

vickers hardness test procedure pdf

vickers hardness test manual

rockwell hardness tester procedure pdf

52 likes, 0 comments - trechosalientes on January 29, 2024: "Técnicas de Amanda leon #cortespagodedaofensa #cortespodcast #pagodedaofensa #AmandaLeon"

vickers hardness test discussion|vickers hardness test procedure pdf